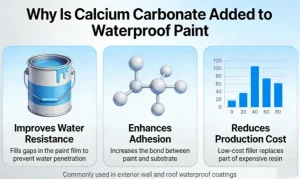

Calcium carbonate (CaCO₃) is added to waterproof paints not because it provides “waterproofing” on its own—it is not inherently waterproof (and is even slightly soluble in water containing CO₂)—but rather to enhance overall paint performance, reduce costs, and improve application properties. When properly formulated, calcium carbonate significantly contributes to the effectiveness of waterproof coatings.

Below are the main reasons why calcium carbonate is included in waterproof paints:

1. Acts as a Functional Filler (Extender)

Calcium carbonate is one of the most widely used inorganic fillers. It partially replaces expensive film-forming resins (e.g., acrylics or polyurethanes), substantially lowering production costs.

It increases the solid content of the paint, reduces film shrinkage during drying, and helps form a denser coating, indirectly improving water resistance.

2. Improves Physical Properties of the Dry Film

Enhances opacity andwhiteness: As a white powder, calcium carbonate boosts hiding power and brightness—especially beneficial for white or light-colored waterproof coatings.

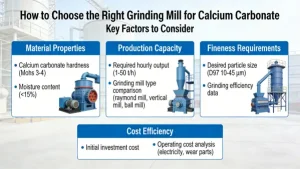

Modifies rheology: Properly sized calcium carbonate (e.g., ground calcium carbonate, GCC, or precipitated calcium carbonate, PCC) improves viscosity, suspension stability, and leveling during application.

Increases mechanical strength: Appropriate addition enhances film hardness, abrasion resistance, and compressive strength, reducing the risk of cracking.

3. Refines Pore Structure, Indirectly Enhancing Waterproofing

In cementitious waterproof coatings (e.g., polymer-modified cementitious slurries), fine calcium carbonate particles can fill micro-pores between cement hydration products, resulting in a denser, less permeable coating.

This “micro-filling effect” is conceptually similar to using mineral admixtures like silica fume in concrete.

✅ Note: This benefit depends on the particle size distributionand dosage of calcium carbonate—excessive or overly coarse filler can introduce defects and weaken waterproof performance.

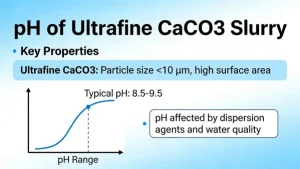

4. Buffers pH and Improves Stability

Calcium carbonate is mildly alkaline (pH ≈ 9–10), helping maintain an alkaline environment in water-based systems, which prevents emulsion coagulation and enhances shelf life.

In cement-based systems, its alkalinity also supports cement hydration reactions.

5. Eco-Friendly and Safe

Calcium carbonate is non-toxic, odorless, and chemically inert, meeting environmental and safety standards for interior applications (e.g., bathroom or kitchen waterproofing).

⚠️ Important Considerations

Calcium carbonate itself is hydrophilic, not hydrophobic. If used in excess or without surface treatment, it may increase water absorption of the coating.

Therefore, in high-performance waterproof paints, calcium carbonate is often surface-modified (e.g., with stearic acid or silane coupling agents) to reduce hydrophilicity and improve compatibility with organic binders.

Premium waterproof formulations typically combine calcium carbonate with true waterproofing agents, such as:

Polymer emulsions (acrylics, VAE)

Hydrophobic additives (organosilicones, wax emulsions)

Platelet-shaped fillers (mica, glass flakes)

Summary

✅ The role of calcium carbonate in waterproof paint includes: • Cost reduction • Improved film density and mechanical properties • Better application behavior and storage stability

❌ However, it is not a primary waterproofing agent and cannot provide waterproofing by itself.

🔬 Proper formulation—including the type,particlesize, dosage, and surface treatment of calcium carbonate—is critical to achieving effective waterproof performance.

Thus, calcium carbonate plays a supportive yet essential role in waterproof coatings—not as the active waterproofing component, but as a key functional additive that optimizes the entire system.