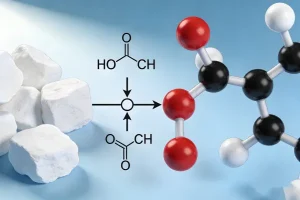

Calcium Carbonate (CaCO₃) is an inorganic compound that contains no sugar in its chemical structure. The presence of sugar in calcium carbonate granules is mainly to improve taste, enhance compliance, and also play a certain auxiliary role in the preparation process. If you find that “calcium carbonate granules contain sugar”, this is usually not a property of calcium carbonate itself, but is caused by the following external factors:

Compound Formulations as Food or Pharmaceutical Additives

Calcium carbonate is often used in food, health products or pharmaceuticals as:

Calcium fortifier (e.g., calcium tablets, high-calcium milk powder)

Anti-caking agent or filler

To improve taste, facilitate molding or enhance stability, manufacturers may add excipients to calcium carbonate granules, such as:

Sugars (e.g., lactose, sucrose, glucose), especially in chewable calcium tablets or calcium supplements for children

Carbohydrates (e.g., starch, dextrin, maltitol), which may be mistaken for “sugar”

✅ These sugars are not derived from carbonate rocks themselves, but are artificially added excipients.

Residues from Production Processes

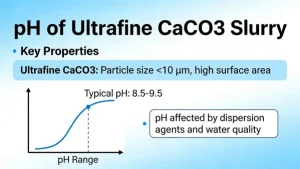

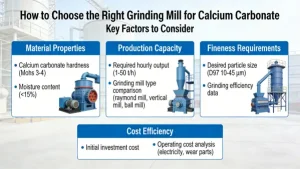

Certain industrial-grade or food-grade calcium carbonate (especially “precipitated calcium carbonate”) may use sugar-containing substances in the production process as:

Dispersants

Surface modifiers

Crystallization control agents (less common, but possible in specific fine chemical industries)

Although residues are removed through washing in standard production processes, trace residues may remain in low-quality products.

Cross-Contamination or Improper Storage

Cross-contamination may occur if calcium carbonate is processed using the same equipment as other sugar-containing materials (e.g., milk powder, sugar powder) or stored in the same environment.

In humid conditions, organic particles in the air or microbial metabolites may also adhere to the surface of the granules.

Misinterpretation of Detection Methods

Certain rapid test strips or non-specific reagents (e.g., Fehling’s reagent, phenol-sulfuric acid method) may misidentify other reducing substances or carbohydrates as “sugar”.

Calcium carbonate itself is non-reducing and does not react with Fehling’s reagent; a positive result indicates the presence of reducing sugars or other interfering substances in the sample.

Adapting to the Formulation Characteristics of Granules

Granule formulations require good solubility and dispersibility. Sugars (especially sucrose) have certain water solubility and adhesiveness, and can be used as fillers or binders in the granulation process.

They help calcium carbonate powder bond into uniform granules, prevent powder dusting, and enable the granules to quickly disperse and dissolve in water to form a stable suspension or solution, making it easier to take and absorb.

Providing Energy (Formulated for Specific Populations)

Some calcium carbonate granules are designed for specific groups such as children, pregnant and lactating women, who have additional energy requirements. The added sugars can quickly provide energy to the body, forming a synergistic effect with calcium supplementation to better meet the nutritional needs of the target population.