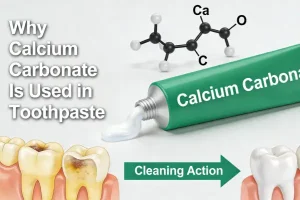

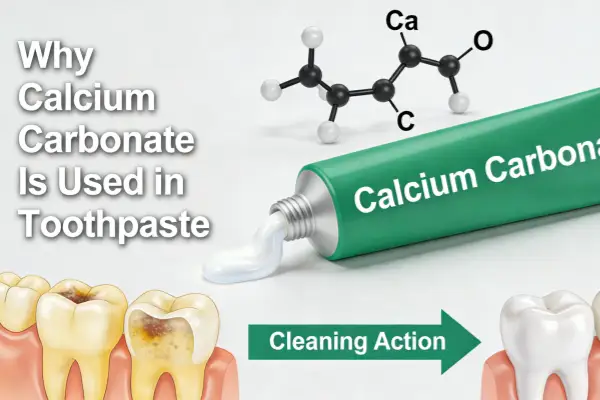

The addition of calcium carbonate (CaCO₃) in toothpaste is a common practice in the industry. Its core role is as an abrasive, and it also has multiple advantages such as auxiliary cleaning and regulating paste performance. Its application logic is closely related to the cleaning principle, user experience and cost control of toothpaste. The specific reasons are as follows:

1. Core Function: Acting as an Abrasive to Efficiently Remove Plaque and Stains

The core purpose of brushing teeth is to mechanically remove plaque, food residues and exogenous stains (such as tea stains, smoke stains, coffee stains) from the tooth surface. The physical properties of calcium carbonate are perfectly suitable for the requirements of abrasives:

Moderate Hardness: The Mohs hardness of calcium carbonate is about 3 (calcite type), which is much lower than that of tooth enamel (Mohs hardness 6-7). It can not only generate sufficient cleaning power through friction but also not wear enamel, avoiding tooth damage;

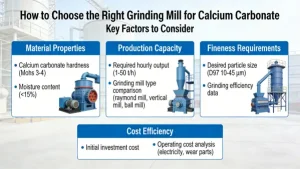

Suitable Particle Morphology: In industrial production, calcium carbonate can be processed into powders of different particle sizes (usually 2-20μm) and shapes (such as irregular particles, spherical particles) to adapt to different types of toothpaste——for example, medium-coarse particle size calcium carbonate is used in ordinary cleaning toothpaste to enhance friction and cleaning power; ultra-fine particle size calcium carbonate is used in sensitive/mild toothpaste to reduce friction irritation;

High Cleaning Efficiency: Calcium carbonate particles are evenly dispersed in the toothpaste. When brushing teeth, they fully contact the tooth surface, quickly peel off stains through physical grinding, and at the same time help remove the plaque biofilm, reducing the risk of tooth decay and periodontal problems.

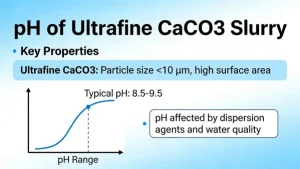

2. Auxiliary Role: Regulating Toothpaste pH Value to Improve Cleaning Comfort

Calcium carbonate is weakly alkaline (aqueous solution pH about 8-9), while the normal pH of the oral environment is 6.5-7.5. A slightly acidic environment is prone to bacterial growth and enamel corrosion. Adding calcium carbonate to toothpaste can appropriately adjust the paste pH to weakly alkaline. On the one hand, it can neutralize a small amount of acidic substances in the oral cavity and alleviate the erosion of teeth by the acidic environment; on the other hand, it can reduce the irritation of acidic substances to the gums and improve the taste comfort when brushing teeth, which is especially suitable for people with sensitive oral cavities.

3. Optimizing Paste Performance to Enhance User Experience

Calcium carbonate is not only a functional ingredient but also can be used as a “filler regulator” to improve the physical state of toothpaste:

Regulating Consistency and Stability: Calcium carbonate powder has a certain oil absorption and thickening property. Adding it to toothpaste can make the paste form a uniform and delicate gel, avoiding the paste being too thin or layered, and improving the ductility and stability of the paste (not easy to deteriorate during long-term storage);

Improving Foaming Effect: The particle structure of calcium carbonate can assist surfactants (foaming components in toothpaste) to form delicate and long-lasting foam. The foam can wrap stains and residues, enhance the uniformity of cleaning, and at the same time improve the refreshment when brushing teeth.

4. High Safety, Suitable for Oral Contact Requirements

Calcium carbonate is a non-toxic and non-irritating inorganic compound, and it is insoluble in water. Most of it is discharged with foam and water after brushing teeth, and a small amount of residue will not be absorbed by the oral mucosa, which is harmless to the human body (meeting the standards of food-grade/oral care-grade raw materials). In addition, calcium carbonate has stable chemical properties and does not react with other components in toothpaste (such as fluoride, surfactants, flavors, etc.), and will not affect the core efficacy of toothpaste (such as anti-cavity, desensitization), making it suitable for various toothpaste formulas.

5. Significant Cost Advantage, Reducing Product Pricing

Calcium carbonate has a wide source (processed from natural limestone and calcite) and a simple production process (crushing, classification, surface modification, etc.). The raw material cost is much lower than that of other high-end abrasives (such as silica, hydroxyapatite). For mass consumer toothpaste, using calcium carbonate as an abrasive can greatly reduce raw material costs while ensuring cleaning effect, which is one of the optimal choices to balance “cost performance” and “function”.

Notes:

Calcium carbonate abrasives are more suitable for “ordinary cleaning” toothpaste. For people with severe enamel wear and tooth sensitivity, some brands will choose milder abrasives (such as silica), which should be selected according to oral conditions;

The amount of calcium carbonate added in toothpaste must be strictly controlled (usually accounting for 20%-40% of the total mass of toothpaste). Excessive addition will lead to too hard paste and too strong friction, while too little will result in insufficient cleaning power. The balance needs to be achieved through formula debugging.