Calcium carbonate is widely used in the processing of PVC (polyvinyl chloride). The core reason is that calcium carbonate can significantly optimize the processing performance of PVC, improve the comprehensive performance of products at a low cost, and expand its application scenarios. It is an inorganic filler with extremely high cost performance in PVC modification. The specific functions can be divided into the following five core dimensions:

1. Reduce Production Costs and Improve Cost-Effectiveness

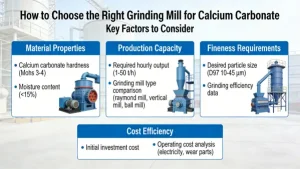

This is the most basic and crucial role of calcium carbonate in PVC. The price of PVC resin is much higher than that of ordinary inorganic minerals such as light calcium carbonate and heavy calcium carbonate. By adding calcium carbonate to replace part of the PVC resin, the raw material cost per unit product can be greatly reduced (usually the dosage of calcium carbonate accounts for more than 25% of the total mass of PVC products, and can reach 40% in some scenarios). In particular, heavy calcium carbonate, due to its simple production process (made by mechanical crushing of natural limestone), has lower cost and is the preferred choice for “increasing volume and reducing cost” of PVC products; even light calcium carbonate and nano-calcium carbonate with better performance are still lower in cost than PVC resin, which can balance economy while ensuring performance.

2. Improve Product Mechanical Properties and Enhance Durability

Pure PVC resin has high brittleness and limited mechanical properties. Calcium carbonate can optimize its mechanical performance through the “skeleton reinforcement” effect:

Improve rigidity and hardness: Calcium carbonate forms a supporting structure similar to “steel bars” in PVC products, significantly improving the hardness and rigidity of rigid PVC (such as pipes and window frames), reducing the risk of deformation and scratching during use, and meeting the requirements for structural strength in construction, engineering and other scenarios;

Improve toughness and impact resistance: Light calcium carbonate or nano-calcium carbonate modified by surface treatment can better compatible and disperse with PVC resin, improving the impact strength and elongation at break of products——for example, nano-calcium carbonate used in PVC pipes can increase the tensile yield strength and bending resistance by 15%-25%, and coated modified calcium carbonate can even increase the unnotched impact strength of PVC by 4 times;

Optimize tensile performance: Heavy calcium carbonate has a significant reinforcing effect on the tensile strength of PVC. By reasonably matching the ratio of light calcium carbonate to heavy calcium carbonate (such as 3:1), both tensile strength and impact strength can be taken into account.

3. Improve Processing Performance and Production Efficiency

Pure PVC is prone to problems such as poor melt fluidity, uneven plasticization, and thermal decomposition during processing. Calcium carbonate can be optimized in a targeted manner:

Regulate melt performance: Calcium carbonate can reduce the melt viscosity of PVC, improve its rheological properties, make the material easier to plasticize and mix uniformly in processes such as injection molding, extrusion, and calendering, and reduce material loss during processing;

Shorten processing cycle: The thermal conductivity of calcium carbonate (about 2.2 W/m·K) is much higher than that of PVC resin (0.2 W/m·K). After adding, it can accelerate the cooling rate of products and improve production efficiency; in PVC foam products, calcium carbonate can also inhibit the excessive expansion of cells, control the cell size to be finer, and improve foam quality;

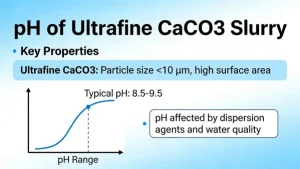

Reduce the risk of thermal decomposition: Light calcium carbonate is alkaline, which can absorb HCl (hydrogen chloride) gas generated by the decomposition of PVC during processing, assist heat stabilizers to play their role, and reduce the yellowing and performance degradation of PVC caused by thermal decomposition.

4. Improve Product Stability and Service Life

Calcium carbonate can enhance the stability of PVC products in different environments and extend their service life:

Optimize dimensional stability: Calcium carbonate can reduce the shrinkage rate, linear expansion coefficient and creep performance of PVC, allowing products to maintain their original shape and dimensional accuracy under conditions such as high and low temperature changes and external extrusion. This is crucial for PVC pipes and profiles that require precise installation;

Improve heat resistance: After adding calcium carbonate, the heat distortion temperature of PVC products is significantly increased——for example, when filling with less than 20% calcium carbonate, the heat resistance temperature of PVC can be increased by 8-13℃, and when filling with 40% heavy calcium carbonate, the heat resistance can even be increased by more than 20℃, reducing softening and deformation in high-temperature environments;

Enhance weather resistance: Calcium carbonate is stable to light and not easy to decompose under ultraviolet radiation. After adding, it can improve the anti-aging ability of PVC products and delay the performance attenuation after long-term outdoor use.

5. Optimize Appearance and Function, Expand Application Scenarios

Calcium carbonate can also improve the appearance texture of PVC products and endow them with some special functions:

Regulate optical properties: Calcium carbonate with whiteness ≥ 90 can improve the whiteness of PVC products and offset the yellow light of pure PVC; when used with titanium dioxide, it can improve the matting property of products, suitable for scenarios such as PVC films for writing and printing; calcium carbonate processed by fine processing (such as wet-process heavy calcium carbonate) can also improve the surface gloss and flatness of products, making doors, windows and decorative profiles more beautiful;

Endow special functions: Ultra-fine or nano-calcium carbonate has a certain flame-retardant effect on PVC, which can be used in scenarios requiring flame retardancy such as wires and cables; in PVC cable materials, calcium carbonate can also improve insulation performance and ensure use safety.

It should be noted that the type of calcium carbonate used in PVC needs to be selected according to product requirements (heavy calcium carbonate has high cost performance, light calcium carbonate has balanced performance, and nano-calcium carbonate is suitable for high-end scenarios), and the dosage should be controlled (excessive dosage is likely to lead to decreased toughness). At the same time, surface modification (such as coupling agent treatment) is used to improve compatibility with PVC, so as to maximize its role.