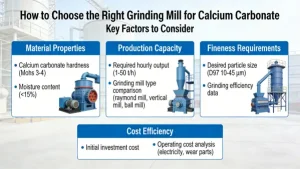

Grinding calcium carbonate is a crucial step in industrial production. The main purpose of grinding calcium carbonate is to achieve fine particle size, optimize particle morphology and distribution through physical crushing and refinement, and change its physical properties to meet the needs of different scenarios.

Improve product application performance

Enhance filling and reinforcement effects: Calcium carbonate is commonly used as a filler in industries such as plastics, rubber, coatings, and papermaking. The superfine calcium carbonate particles after grinding are finer and have larger specific surface area, which can be more evenly dispersed in the matrix material, and improve the mechanical properties (such as strength and toughness), wear resistance and aging resistance of products. For example, adding ultrafine calcium carbonate to plastic film can improve its tensile strength and barrier properties.

Improving optical and appearance characteristics: Calcium carbonate with finer particle size can reduce light scattering and obstruction, and when used in coatings and papermaking, it can enhance the glossiness of coatings, the whiteness and smoothness of paper.

Optimize processing performance: Refined calcium carbonate particles have better flowability and are easier to mix evenly with other raw materials during production, reducing equipment wear and improving production efficiency.

Expand application areas

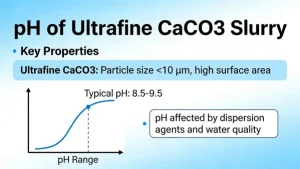

The application range of ordinary calcium carbonate is limited, while the nanometer and micrometer sized ultrafine calcium carbonate obtained by grinding can meet the needs of high-end fields. For example, nano calcium carbonate can be used in lithium battery separators, pharmaceutical carriers, cosmetic raw materials, etc. These fields require extremely high particle size and purity of calcium carbonate.

Enhance economic value

The value of unpolished calcium carbonate ore is relatively low. After graded grinding and processing, different grades of products can be produced according to different particle sizes. The price of ultrafine calcium carbonate is much higher than that of ordinary calcium carbonate, which can significantly increase the added value of the product.

In addition, during the grinding process, supporting processes such as grading and modification can be used to further adjust the particle shape (such as spindle shape, cubic shape) and surface properties of calcium carbonate, making it more suitable for specific industry needs.