Key Functions of Calcium Carbonate Surface Modification

Surface modification is a core method for transforming mineral fillers from ordinary extender fillers into functional fillers. Its primary goal is to optimize surface properties and address application pain points, while achieving dispersion, viscosity reduction, filling enhancement, and interfacial mechanical strengthening. The commonly used modification methods include chemical modification, coating modification, and mechanochemical modification.

Purpose of Surface Modification

Enhance Compatibility and Adaptability

Surface modification improves the affinity between calcium carbonate and organic materials such as rubber and plastics, enabling better integration. For example, after treatment with titanate coupling agents, its compatibility with polymer molecules is significantly enhanced, which can remarkably improve the mechanical properties of thermoplastic composites, including impact strength, tensile strength, flexural strength, and elongation at break.

Improve Dispersion Uniformity

The finer the particle size of calcium carbonate, the higher its quality. However, fine particles have high surface energy and are prone to adsorption and agglomeration. After surface modification, modifiers adsorb on the particle surface and impart charge characteristics, reducing agglomeration and ensuring uniform dispersion of calcium carbonate in the matrix material, thus stabilizing product performance.

Reduce Oil Absorption Loss

Modified calcium carbonate exhibits more uniform dispersion, with reduced gaps between and within particles. Meanwhile, modified molecules cover the surface, weakening polarity and reducing friction between particles, leading to denser particle packing. This effectively lowers the oil absorption value and reduces the consumption of matrix materials in applications.

Expand High-End Application Fields

With good affinity and low oil absorption, modified calcium carbonate can be widely used in high-end scenarios such as plastics, coatings, rubber, papermaking, sealants, and breathable films. It not only improves the quality of end products but also helps downstream enterprises reduce costs, breaking the application limitations of ordinary calcium carbonate.

Increase Product Added Value

The market for ordinary calcium carbonate suffers from overcapacity and fierce low-price competition. Surface-modified calcium carbonate offers significantly improved usability and user experience, leading to higher product prices and added value. This helps enterprises break away from low-price competition and expand profit margins.

Endow Diversified Functions

Surface modification enables calcium carbonate to gain new functions: coating with silica can partially replace fumed silica; coating with metals enhances the special properties of rubber products; coating with titanium dioxide can substitute part of titanium dioxide; treatment with phosphates or other substances can produce acid-resistant calcium carbonate, expanding application boundaries.

Basic Process Conditions for Surface Modification

01

The modifier shall be pretreated by dilution, emulsification, spraying, or other methods to improve its own dispersion, laying a foundation for subsequent coating.

02

Prioritize the continuous spraying or dripping mode linked with the continuous feeding of powder to ensure the synchronization and adaptation between modifier addition and material transportation.

03

Accurately regulate the system temperature and reaction time to match the modification mechanism and the modifier’s requirements for process conditions, ensuring the full progress of the modification reaction or coating process.

04

Precisely measure the modifier and materials separately to achieve uniform addition and feeding, ensuring the instantaneous accuracy of their proportioning ratio.

05

Pay attention to auxiliary supporting facilities and environmental factors: rationally use supporting equipment such as dispersers and classifiers, and control external conditions including ambient temperature and humidity.

06

Optimize equipment operating parameters and conduct regular maintenance of equipment status to ensure stable equipment operation and maintain process consistency.

Three Mainstream Modification Production Processes

Continuous Modification Production Process

The continuous modification production process is mostly connected after the dry powder preparation process, focusing on large-scale continuous production of non-metallic mineral active powders. Such powders are widely used as inorganic fillers or pigments in polymer-based composites such as plastics, rubber, and adhesives.

The core of this process is to realize continuous powder feeding and continuous modifier addition. Therefore, in addition to the main modification equipment, it is necessary to match continuous feeding devices and precise modifier addition devices. Its production equipment is significantly different from batch-type equipment, which can meet the large-scale production needs of large enterprises and adapt to high-yield scenarios.

Batch Modification Production Process

The batch modification production process allows wide adjustment of time and temperature, and has strong adaptability to different modifiers and composite formulas. It is especially suitable for the surface chemical modification of small and medium-batch powders, such as silane coupling agent modification scenarios.

Key parameters including rotation speed, temperature, processing time, material filling rate and modifier addition method need to be controlled during operation. The specific process is: put the measured powder raw materials and prepared modifier into the modification equipment together, complete modification at a set temperature for a specified time, unload the finished product, and then reload for the next batch. It is usually used with an air classifier to separate agglomerated particles and improve product uniformity.

Composite Modification Production Process

The composite modification production process is an integrated modification scheme with multiple equipment linkage. The core is to add surface modifiers synchronously during mechanical force action or fine grinding and ultra-fine grinding processes. While reducing the powder particle size, the chemical coating modification of the particle surface is completed.

This process combines the advantages of continuous and batch processes, with uniform and strong adhesion of modifiers, high process controllability, and stable product quality. In practical applications, it is often matched with a depolymerizer or classifier to further optimize product dispersibility and particle size distribution.

Equipment and Processes We Can Provide

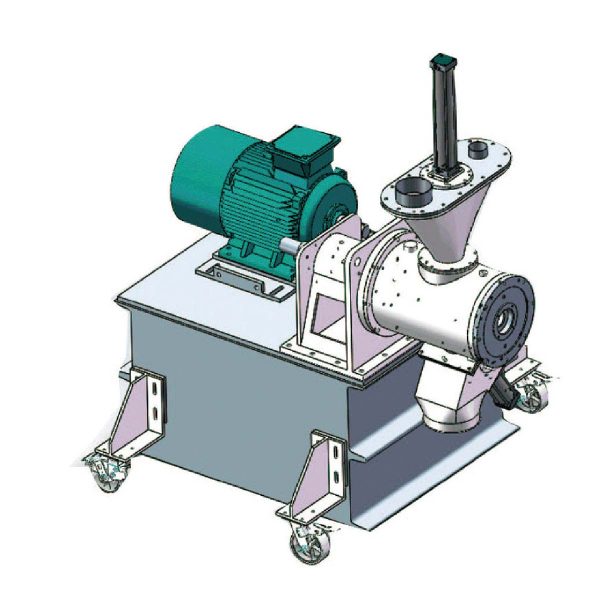

Cyclone Mill Modification Process

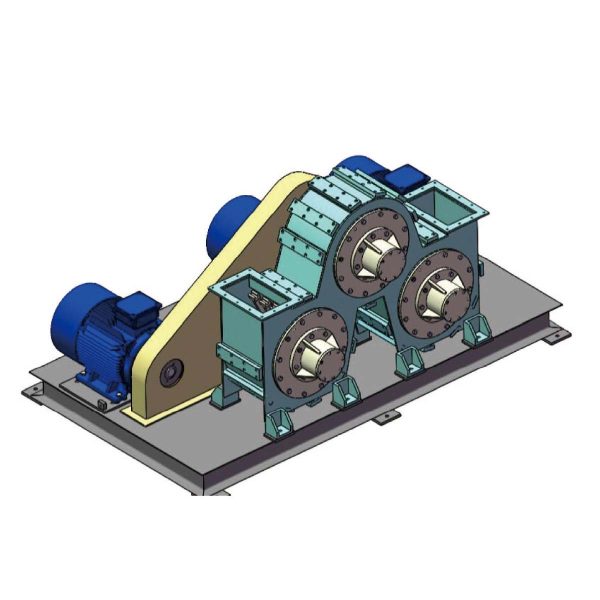

Turbo Mill Modification Process

Three-roller Mill Modification Process

Pin Mill Modification Process