The core of the calcium carbonate crushing method is to break the crystal structure and inter-particle bonding force of calcium carbonate raw materials through mechanical force, process natural calcium carbonate ores (such as calcite, marble, limestone, etc.) or bulk raw materials into powders of different fineness. At the same time, a classification system is used to screen qualified products, and unqualified materials are recycled for re-crushing to achieve closed-loop production. Its principle can be decomposed according to the core links of “crushing – grinding – classification”. The specific action mechanisms of different process equipment are slightly different, but the core logic is consistent:

1. Principle of Pretreatment and Crushing

First, screen the raw materials to remove gangue and other impurities, then perform coarse crushing with a crusher (such as a jaw crusher): use impact and extrusion to crush large ore into small particles within 30mm, reducing the feed size threshold for the subsequent grinding link, and avoiding large particles from damaging the grinding equipment or affecting the crushing efficiency. Some fine crushing equipment will further reduce the particle size through secondary actions such as reciprocating extrusion and vibration impact, improving the uniformity of subsequent grinding.

2. Core Grinding Principle

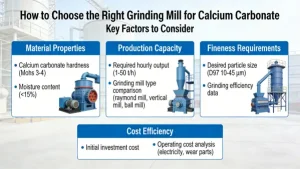

Grinding is the key link of the crushing method. Different grinding equipment (Raymond mill, ring roller mill, ball mill, ultra-fine vertical mill, etc.) achieve crushing through different combinations of mechanical forces. The core mechanisms include four types: extrusion, grinding, shearing, and impact:

Raymond mill/ultra-fine vertical mill: Under the action of centrifugal force or hydraulic pressure, the grinding roller is pressed tightly against the grinding ring. The material is sent into the gap between the grinding roller and the grinding ring by a scraper, and is crushed by the extrusion and grinding force generated by the relative movement of the two. Hydraulic control can increase the rolling pressure and improve the crushing efficiency;

Ring roller mill: When the turntable drives the grinding roller to revolve, the grinding roller is thrown to the grinding ring by centrifugal force and rotates on its own. When the material passes through the gap, it is subjected to impact, extrusion and grinding at the same time. Some equipment adopts a double-layer grinding roller structure to achieve secondary crushing and improve the sufficiency of crushing;

Ball mill: When the grinding cylinder rotates, the internal grinding media (steel balls, quartz sand, etc.) fall and roll under the action of gravity and centrifugal force, and the material is crushed by the impact and grinding between the grinding media and the material.

3. Principle of Classification and Collection

The ground powder enters the classifier (analyzer) with the air flow, and the screening accuracy is controlled by adjusting the rotating speed of the classification wheel: the higher the rotating speed, the finer the screened powder. Qualified fine powder enters the cyclone separator or pulse dust collector with the air flow for separation and collection. Unqualified coarse powder falls due to gravity and flows back to the grinding chamber for reprocessing, forming a closed loop of “grinding – classification – recycling” to ensure uniform product fineness.

This method is mainly used for the production of ground calcium carbonate (GCC). The whole process is a physical change that does not change the chemical properties of calcium carbonate, which is different from the chemical synthesis method of precipitated calcium carbonate (PCC). The air flow system is mostly a closed loop (combined positive and negative pressure), which not only ensures the utilization rate of materials but also reduces dust pollution.