Turbo Mill Modification Process

How it works

Performance and features

Integrated Particle Dispersion and Modification

Integrates particle dispersion and surface modification functions, eliminating the need for additional processes, improving operational efficiency, and significantly reducing running costs.

Superior Wear-Resistant Design for Calcium Carbonate

Key chamber components are made of wear-resistant materials, adapted to the high-abrasion characteristics of calcium carbonate powder, and avoiding frequent maintenance that affects continuous production.

Highly Flexible Accessory Compatibility

Stator grooves and wear-resistant liners support disassembly and replacement. Accessory specifications can be adjusted according to the crystal form of calcium carbonate to meet diverse modification requirements.

Classified Processing Ensures Product Quality

Optional built-in classification structure allows coarse calcium carbonate particles to be recycled and dispersed inside the machine, ensuring consistent product monodispersity and particle size uniformity.

Airflow Circulation Delivers Significant Energy Savings

Relying on the built-in high-intensity vortex airflow, powder dispersion and impurity removal are achieved simultaneously during the dispersion and modification process, eliminating the need for additional air supply and saving 30%-50% energy compared with traditional processes.

Adapted to Diverse Calcium Carbonate Requirements

Compatible with various types of calcium carbonate powder including precipitated calcium carbonate (PCC) and ground calcium carbonate (GCC), supports the application of different modifier formulas, and meets the material standards of multiple downstream industries.

Technical Parameters

| Parameters / Model | 40 | 60 | 80 | 100 | 120 | 150 |

|---|---|---|---|---|---|---|

| Rotor diameter (mm) | 390 | 540 | 730 | 950 | 1150 | 1450 |

| Rotor speed (r/min) | 4200 | 3075 | 2100 | 1800 | 1490 | 1250 |

| Particle size (μm) | 10~400 | 10~400 | 10~400 | 10~400 | 10~400 | 10~400 |

| Air volume(max) (m³/min) | 3000 | 4500 | 6000 | 7500 | 9000 | 12000 |

| Output (kg/h) | 30~800 | 80~2000 | 100~3000 | 200~4500 | 300~6000 | 500~10000 |

| Power (kW) | 30~37 | 45~55 | 75~90 | 90~110 | 110~160 | 160~250 |

| Net weight (kg) | 600 | 1600 | 3000 | 4500 | 7000 | 12000 |

Related Processes & equipment

Cyclone Mill Modification Process

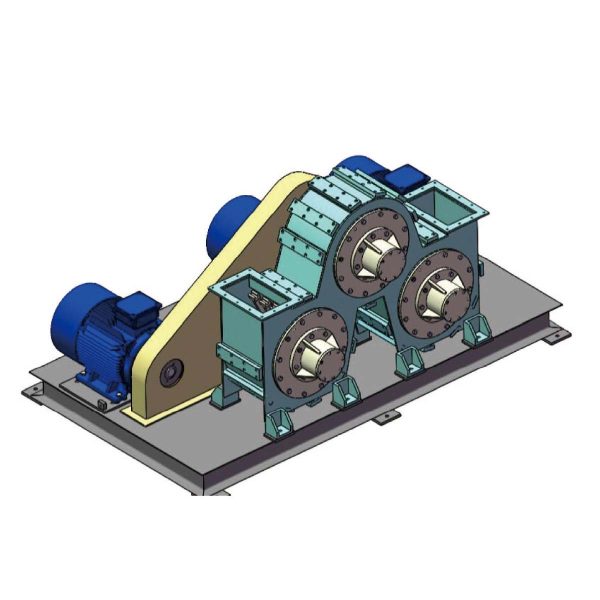

Three-roller Mill Modification Process

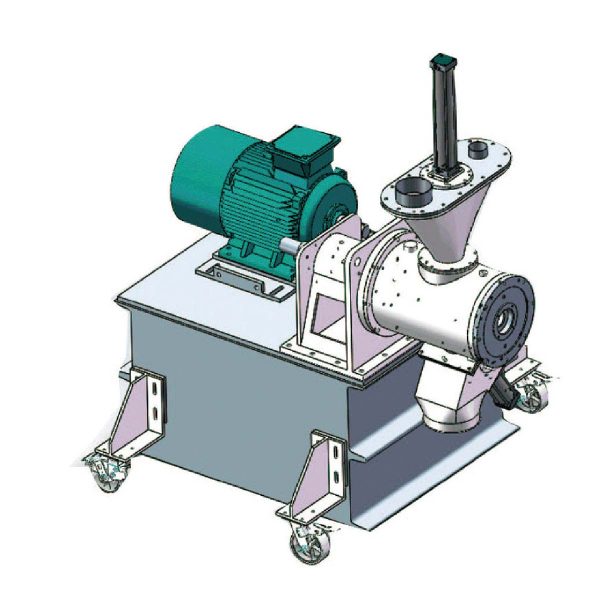

Pin Mill Modification Process