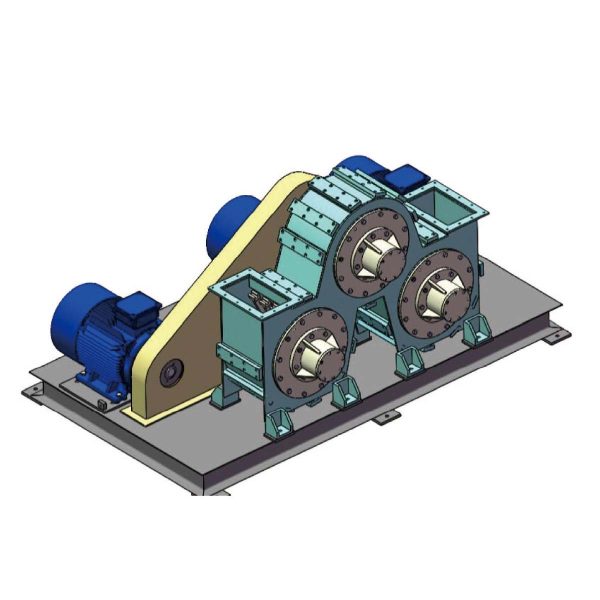

Three-roller Mill Modification Process

How it works

Performance and features

Mature and Cost-Effective Process

The technology is mature and stable in application, with low equipment investment cost, and is particularly suitable for the coating modification of calcium carbonate powder with stearic acid-based modifiers.

High-Efficiency Self-Friction Heat Generation

It relies on the heat generated by friction between the rotors and calcium carbonate materials as well as between the materials themselves, eliminating the need for additional heating devices, reducing auxiliary equipment, and greatly simplifying the calcium carbonate modification process flow.

Clear Particle Size Adaptation Range

It is specially designed for the surface modification of 325–1250 mesh calcium carbonate powder, with well-defined particle size adaptation boundaries to meet the processing needs of powder within this range.

Insufficient Powder Dispersion Performance

The equipment has relatively low air volume, resulting in poor dispersibility of calcium carbonate powder. Fine powder particles are highly prone to agglomeration, requiring an increased dosage of modifiers to ensure coating effectiveness.

Difficulty in Modification Temperature Control

Relying on the self-friction heat generation mode, the temperature is easily affected by factors such as feed rate and ambient temperature, making it difficult to precisely control the calcium carbonate modification temperature and potentially causing product quality fluctuations.

Limited Overall Coating Efficiency

There are material dead zones inside the equipment, where some calcium carbonate particles cannot fully contact the modifiers, leading to a low overall coating rate and affecting the consistency of product performance.

Technical Parameters

| Parameters / Model JSGX | 200 | 300 | 600 | 900 |

|---|---|---|---|---|

| Main motor power (kW) | 4×3 | 18.5×3 | 37×3 | 75×3 |

| Fan power (kW) | 2.2 | 5.5 | 22 | 30 |

| Main shaft speed (rpm) | 6000 | 4500 | 2700 | 2000 |

| Output (kg/h) | 20~80 | 500~1500 | 1000~3000 | 2500~6000 |

Related Processes & equipment

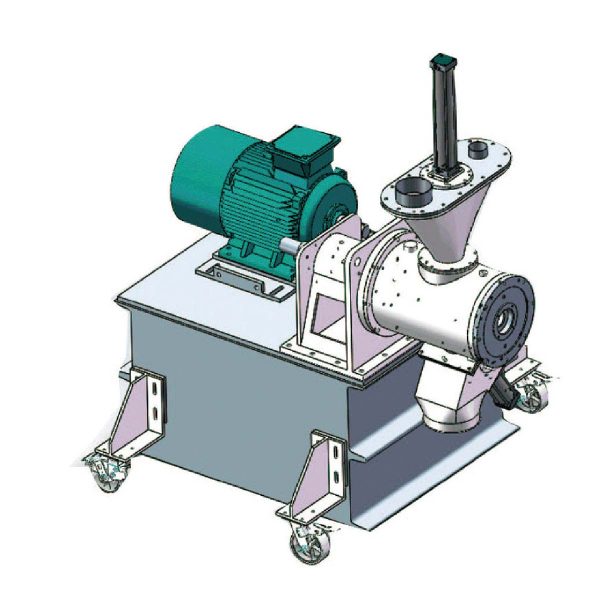

Cyclone Mill Modification Process

Turbo Mill Modification Process

Pin Mill Modification Process