Pin Mill Modification Process

How it works

Performance and features

Wide Application Range

It can efficiently activate and modify various inorganic mineral powders, and is particularly suitable for different types of calcium carbonate powders such as precipitated calcium carbonate (PCC) and ground calcium carbonate (GCC). There is no need to modify the core structure of the equipment to meet the diverse surface modification processing requirements of calcium carbonate.

Excellent Coating Effect

It can accurately measure the ratio of calcium carbonate materials to modifiers, ensure their full contact and uniform coating, effectively improve the surface activity of calcium carbonate particles, and produce finished powders with stable quality, which can better meet the stringent standards of downstream applications.

Comprehensive Modification Functions

The calcium carbonate powder after treatment has significantly improved dispersibility, with the prominent advantages of viscosity reduction and filling enhancement. At the same time, it can strengthen the interface bonding performance between calcium carbonate and polymer materials, providing a better raw material foundation for subsequent product processing.

Economical and Convenient Operation

The equipment has a high degree of automation and outstanding processing efficiency in calcium carbonate modification, which can effectively shorten the production cycle and reduce labor and operation costs. The modified calcium carbonate can be widely used in plastics, rubber and other fields to improve the comprehensive performance of products.

Technical Parameters

| Parameters / Model | 250 | 360 | 500 | 630 | 800 | 1000 |

|---|---|---|---|---|---|---|

| Grinding disc diameter (mm) | 250 | 400 | 500 | 630 | 800 | 1000 |

| Maximum speed on Case side (r/min) | 8000 | 5200 | 4200 | 3300 | 2800 | 2250 |

| Maximum speed on Door side (r/min) | 4500 | 4000 | 3600 | 3000 | 2500 | 2000 |

| Case side Power (kW) | 11 | 37 | 45 | 55 | 90~110 | 132~160 |

| Door side Power (kW) | 7.5 | 22 | 30 | 55 | 90~110 | 132~160 |

| Particle size (mesh) | 20~120 | 20~120 | 20~120 | 20~120 | 20~120 | 20~120 |

| Output (kg/h) | 100~600 | 200~1000 | 400~2000 | 1000~5000 | 2000~8000 | 3000~12000 |

Related Processes & equipment

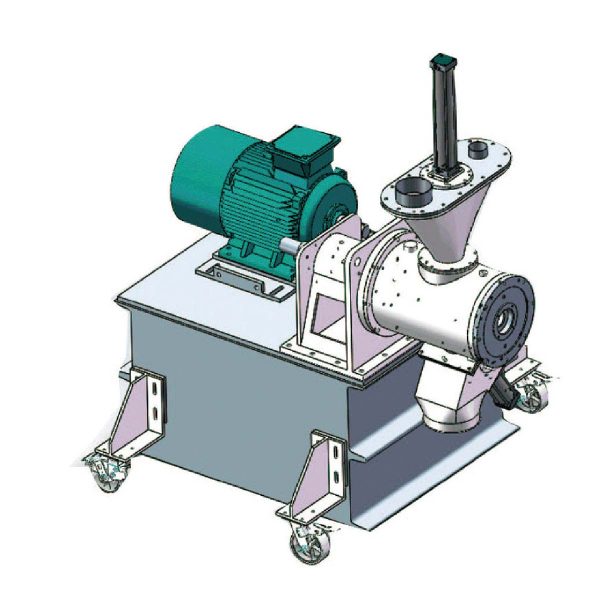

Cyclone Mill Modification Process

Turbo Mill Modification Process

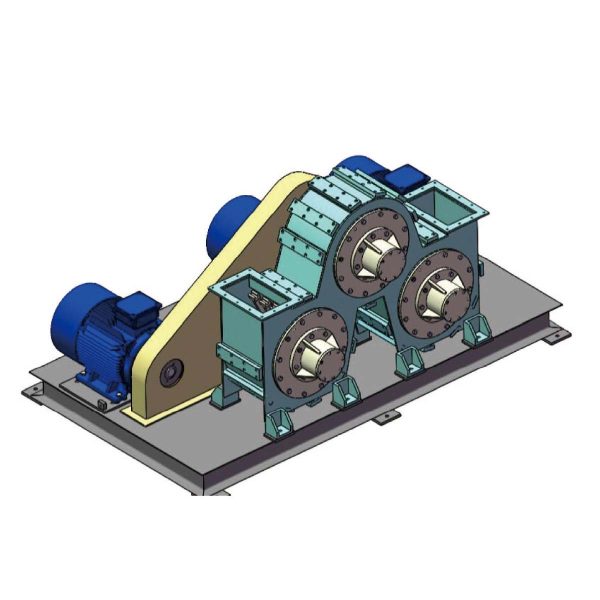

Three-roller Mill Modification Process