Mechanical Fusion Machine Modification Process

How it works

Performance and features

Temperature and Time Controllable

Equipped with professional heating and timing functions, the modification temperature and reaction time can be precisely adjusted. It can flexibly meet the modification reaction requirements of different calcium carbonate powders such as precipitated calcium carbonate (PCC) and ground calcium carbonate (GCC), ensuring a stable and controllable modification process.

Wide Application Range

It can achieve ideal activation and modification effects for various inorganic mineral powders through mechanical fusion. It is especially suitable for calcium carbonate powders of different mesh sizes and types, fully improving their surface activity to satisfy diverse processing needs.

Adequate Coating

Relying on the coordination of uniform feeding and quantitative feeding of modifiers, combined with the strong mixing effect of mechanical fusion, it enables full contact between modifiers and calcium carbonate particles, ensuring each powder particle is adequately coated and improving product consistency.

Thorough Reaction

Through the system’s precise control of temperature and time, coupled with the auxiliary enhancement of mechanical force, it provides optimal conditions for the modification reaction of calcium carbonate powder, ensuring the coating reaction between modifiers and powder particles proceeds fully and enhancing the performance of the finished powder.

Binder-Free Surface Coating, Streamlined Process with Controllable Purity

It can achieve uniform surface coating of calcium carbonate particles with different particle sizes without adding any binders. While simplifying the production process, it avoids the introduction of external impurities, ensures the purity of calcium carbonate powder, and improves the stability and reliability of modification processing.

Technical Parameters

| Parameters / Model / Horizontal | 130 | 300 | 450 | 700 |

|---|---|---|---|---|

| Max installed power (kW) | 7.5 | 30 | 55 | 110 |

| Max operating speed (rpm) | 6000 | 2600 | 1700 | 110 |

| Max feeding capacity (L) | 0.5 | 10 | 30 | 100 |

| Parameters / Model / Vertical | 50 | 300 | 600 | 1000 |

|---|---|---|---|---|

| Max installed power (kW) | 5.5 | 30 | 75 | 150 |

| Max operating speed (rpm) | 3000 | 1500 | 1100 | 900 |

| Max feeding capacity (L) | 3 | 20 | 80 | 200 |

Related Processes & equipment

Cyclone Mill Modification Process

Turbo Mill Modification Process

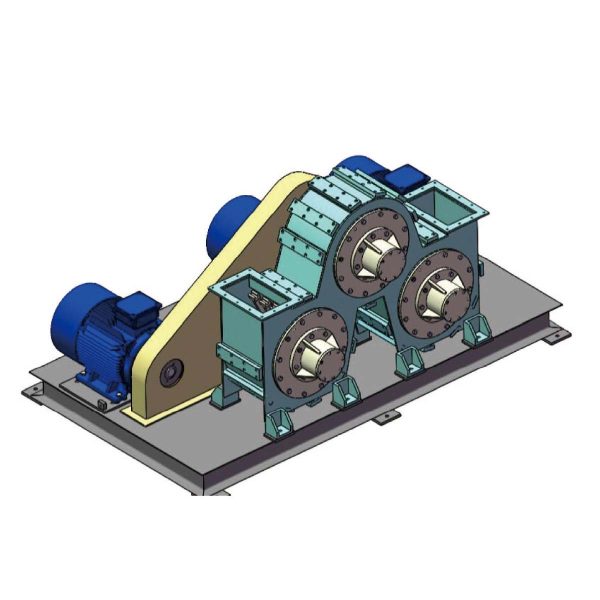

Three-roller Mill Modification Process