Cyclone Mill Modification Process

How it works

Performance and features

Efficient and Uniform Dispersion & Coating

The strong airflow generated during equipment operation creates a cyclone effect. Combined with the optimized flow field design for calcium carbonate particles inside the chamber, materials are dispersed without blind spots. Modifiers fully contact the surface of calcium carbonate particles, significantly improving coating rates and effectively addressing the issues of high hydrophilicity and easy agglomeration of calcium carbonate powder.

Wide Particle Size Adaptability

Equipped with adjustable classifying impellers and screens of different apertures, it meets the coating modification requirements of calcium carbonate powder across various particle size specifications. It is also suitable for fibrous, soft, and medium-to-high hardness calcium carbonate materials, featuring strong applicability to match the application standards of different downstream industries.

Stable Product Quality

The system adopts variable frequency control to optimize particle size adjustment. Some models are equipped with temperature control design to prevent problems such as reduced whiteness of calcium carbonate materials and decomposition of modifiers caused by high temperatures, ensuring consistent modification processes and stable, controllable performance of finished calcium carbonate products.

High Level of Automation

Configured with precision metering and feeding devices as well as negative pressure conveying systems, it realizes automatic and quantitative supply of modifiers. It ensures controllable dosage and low loss, greatly reducing the production cost of calcium carbonate modification while avoiding errors caused by manual addition.

Flexible and Adjustable Process

By adjusting rotor speed, classification parameters, and air draft intensity, it can flexibly adapt to the reaction requirements of different types of modifiers and calcium carbonate particles. It also supports seamless connection with upstream and downstream equipment such as calcium carbonate crushing and classification systems, offering excellent compatibility.

Energy-Saving and Easy Maintenance

Integrating crushing, classification, and coating functions in one, it avoids over-crushing of calcium carbonate materials and achieves lower energy consumption than traditional processes. The wearing parts are easy to replace, and the airflow inside the chamber enables automatic cleaning, reducing equipment maintenance costs and downtime.

Technical Parameters

| Parameters / Model | 300 | 480 | 750 | 1000 | 1250 | 1500 |

|---|---|---|---|---|---|---|

| Rotor diameter (mm) | 300 | 480 | 750 | 1000 | 1250 | 1500 |

| Rotor speed (r/min) | 7800 | 4775 | 3183 | 2387 | 1910 | 1550 |

| Particle size (μm) | 5~250 | 5~250 | 5~250 | 5~250 | 5~250 | 5~250 |

| Air volume(max) (m³/min) | 1200 | 2100 | 3300 | 4500 | 5100 | 6500 |

| Output (kg/h) | 30~800 | 80~2000 | 100~3000 | 200~4500 | 300~6000 | 400~10000 |

| Power (kW) | 18.5 | 45 | 75 | 110 | 132~160 | 160~200 |

| Net weight (kg) | 500 | 1100 | 2300 | 3000 | 3600 | 6000 |

Related Processes & equipment

Turbo Mill Modification Process

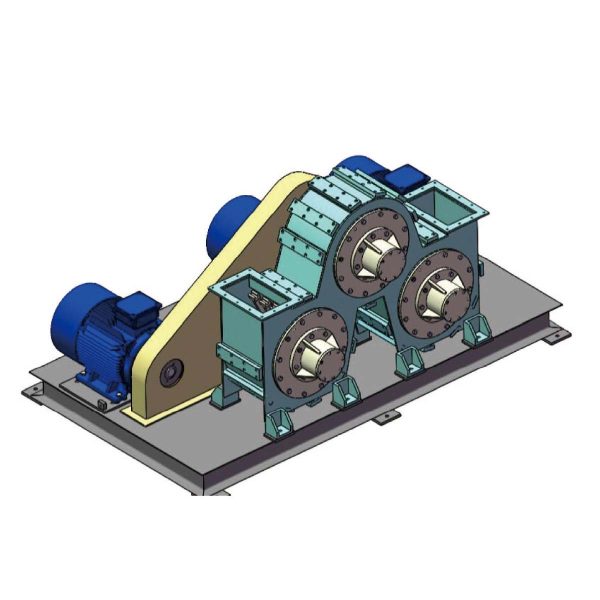

Three-roller Mill Modification Process

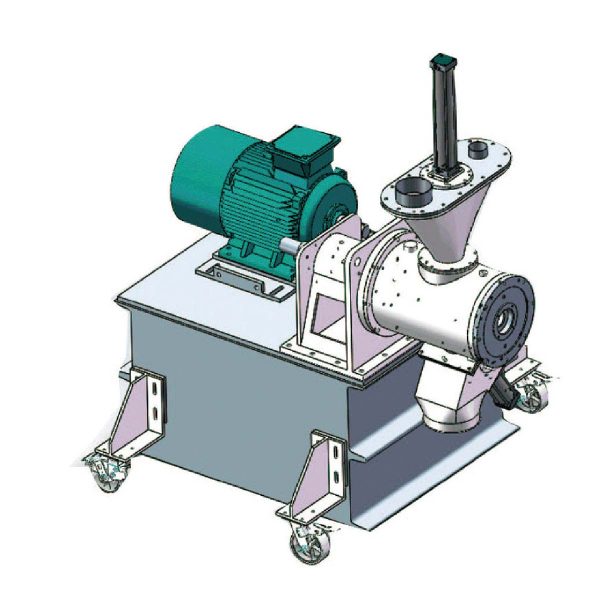

Pin Mill Modification Process