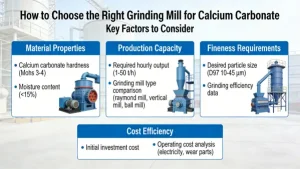

To grind calcium carbonate into a finer powder, the core process consists of pre-treatment first → selection of corresponding dry/wet grinding process → closed-circuit classification → drying and collection, while controlling grinding media, additives, parameters and classification accuracy. There are distinct differences in equipment selection between laboratory and industrial-scale production.

I. Pre-treatment and Coarse Crushing (General Prerequisites)

Raw material purification: Remove gangue and moisture from the ore (control moisture content at 1%–2% to avoid caking).

Coarse crushing → medium-fine crushing: Use a jaw crusher followed by an impact crusher or cone crusher to reduce large raw material lumps to less than 10 mm, then pre-grind to 325 mesh (approximately 45 μm) with a Raymond mill or ball mill to provide uniform feedstock for ultra-fine grinding.

Laboratory small-batch processing: First crush the material to millimeter scale with a jaw crusher or mortar and pestle, then sieve it for subsequent use.

II. Core Grinding Processes (Selected Based on Target Fineness)

| Process | Applicable Fineness | Core Equipment | Key Parameters and Operational Points | Advantages and Disadvantages |

| Dry Grinding | 400–2500 mesh (38–5 μm); jet mill can achieve below 1 μm | Ultra-fine vertical mill, ring-roller mill, jet mill, mechanical impact mill | 1. Vertical mill: Coordinate roller pressure, air velocity and classifier wheel speed; <br> 2. Jet mill: Use compressed air at 0.7–0.8 MPa and adopt frequency conversion for classifier wheel; <br> 3. Ensure uniform feed rate, control temperature below 80℃ and prevent agglomeration | Advantages: Short process flow, low energy consumption, no wastewater discharge; <br> Disadvantages: Prone to agglomeration, efficiency decreases for ultra-fine grinding (below 3 μm) |

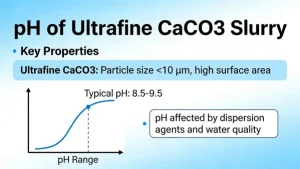

| Wet Grinding | Ultra-fine/nano-scale (d97 ≤ 3 μm, even below 1 μm) | Wet stirred mill, sand mill, flaker (multi-stage series connection or circulation) | 1. Maintain slurry concentration at 60%–70% and add dispersants (e.g., sodium hexametaphosphate at 0.2%–0.5%); <br> 2. Grinding media: Zirconia beads (0.1–0.8 mm, particle size matched to target fineness); <br> 3. Adjust grinding time/circulation times based on particle size test results | Advantages: Uniform particle size, no agglomeration, can be directly used as slurry; <br> Disadvantages: Requires dehydration and drying, with wastewater treatment needed |

| Laboratory Process | Small-batch production (gram to kilogram scale) | Planetary ball mill, vibratory ball mill | 1. Adopt ball-to-material ratio of (10–20):1 and rotational speed of 300–600 rpm; <br> 2. Dry grinding: Add a small amount of grinding aids (e.g., stearic acid); Wet grinding: Use ethanol/water plus dispersants; <br> 3. Conduct batch grinding, stop the machine for particle size testing every 30 minutes to avoid overheating | Advantages: Flexible and controllable; Disadvantages: Low productivity, requires multiple classification steps |

III. Fine Classification + Closed-Circuit Grinding (Determines Final Fineness)

Classification equipment: For dry grinding, use dynamic classifiers or cyclone classifiers (frequency conversion speed regulation to separate qualified fine powder); for wet grinding, use small-diameter hydrocyclones or disc classifiers; in laboratories, use standard sieves or centrifugal classifiers.

Closed-circuit control: Return unqualified coarse powder to the grinding chamber compulsorily to form a closed loop of “grinding → classification → re-feeding”, avoiding over-grinding and energy waste.

Fineness testing: Use a laser particle size analyzer (e.g., Malvern Mastersizer) for online/offline testing of d50 and d97. and adjust grinding and classification parameters in real time.

IV. Drying, Collection and Anti-agglomeration (Industrial/Laboratory)

After wet grinding: Dehydration (filter pressing/centrifugation) → drying (flash drying/spray drying at 100–120℃ to reduce moisture content below 0.5%) → activation (optional, with coupling agents added).

Dry collection: Combine pulse dust collectors with cyclone separators to prevent dust leakage.

Anti-agglomeration measures: Add grinding aids/dispersants during grinding; store finished products under nitrogen protection or add anti-caking agents; adopt vacuum packaging for ultra-fine powders.

V. Typical Process Examples

Industrial dry grinding (1250 mesh): Raw ore → jaw crushing → Raymond mill pre-grinding → ultra-fine vertical grinding → dynamic classification → pulse dust collection → finished product.

Industrial wet grinding (paper coating grade, below 2 μm): Raw ore → jaw crushing → Raymond mill pre-grinding → wet stirred grinding (multi-stage circulation) → hydrocyclone classification → filter pressing → flash drying → activation → packaging.

Laboratory process (nano-scale): Calcium carbonate powder → planetary ball milling (with zirconia beads + ethanol + sodium hexametaphosphate) → grinding for 4–8 hours → centrifugal classification → vacuum drying → finished product.

VI. Key Optimization and Precautions

Grinding aids/dispersants: For dry grinding, add stearic acid or triethanolamine; for wet grinding, add sodium hexametaphosphate or sodium polyacrylate at a dosage of 0.1%–0.5% to reduce energy consumption and prevent agglomeration.

Grinding media: Smaller particle size leads to finer grinding fineness, but it must match the equipment power.

Temperature control: Frictional heating during grinding tends to cause material agglomeration; control temperature below 80℃, and use water cooling if necessary.

Safety and environmental protection: Equip dust removal systems for dry grinding processes; ensure wastewater from wet grinding is treated up to standard before discharge.