Eggshells can be ground into calcium carbonate, and the main component of eggshells is calcium carbonate itself (accounting for about 93%–95%), with the remaining components being mostly calcium phosphate, magnesium carbonate, and a small amount of organic matter. Grinding eggshells into powder is essentially a physical refinement process of natural calcium carbonate raw materials. The specific steps and precautions are as follows:

1. Steps for Grinding Eggshells into Calcium Carbonate Powder

Pretreatment: Impurity Removal and Degreasing

Eggshells need to be cleaned thoroughly to remove residual egg liquid and stains on the surface, so as to avoid peculiar smell or impurities in the powder after grinding.

The cleaned eggshells are put into an oven (temperature controlled at 105–120℃) for drying, or air-dried naturally until completely dry. The purpose is to remove moisture to prevent caking during grinding, and to eliminate residual organic oils at the same time.

If high-purity calcium carbonate is required, the dried eggshells can be calcined at high temperature in a muffle furnace (temperature about 800–900℃) to decompose the organic matter and a small amount of impurities. After calcination, the eggshells will turn into loose calcium oxide. After hydration with water and subsequent carbonation, calcium carbonate with higher purity can be obtained (similar to the preparation process of light calcium carbonate).

Crushing: Reducing Particle Size

Dried eggshells are relatively brittle, but direct grinding is inefficient. A crusher (such as a small jaw crusher or hammer crusher) or manual crushing can be used first to break the eggshells into small particles of 5–10 mm.

Grinding: Refining the Powder

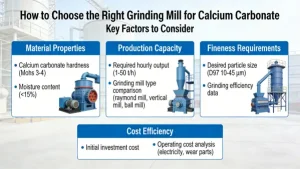

Select grinding equipment according to the target fineness:

– Ordinary fineness (200–400 mesh): Household food processors or grinders can achieve this, which is suitable for small-scale preparation; in industry, Raymond mills can be used, featuring low cost and high efficiency.

– Ultra-fine fineness (above 800 mesh): Ball mills (dry/wet process) or jet mills are required. A small amount of grinding aids (such as ethanol) can be added during grinding to prevent powder agglomeration and improve grinding efficiency.

Classification and Purification

The ground powder is screened through sieves or classifiers to remove unqualified coarse particles; if high purity is required, residual impurities can be removed by pickling and water washing, followed by drying to obtain high-purity eggshell calcium carbonate powder.

2. Precautions

If the organic matter in eggshells is not completely removed, the ground powder may decompose in high-temperature application scenarios (such as plastic processing), resulting in peculiar smell or bubbles. Therefore, it is recommended to add a calcination step for high-demand scenarios.

The powder prepared by household grinding equipment has a wide particle size distribution. If uniform particle size is needed, industrial-grade classification and grinding equipment is recommended.

3. Application Scenarios of Eggshell Calcium Carbonate

– Agricultural field: Used as calcium fertilizer and feed additive to supplement calcium required by animals and plants.

– Industrial field: Used as filler in coatings, plastics and rubber, with a cost much lower than that of natural calcite calcium carbonate.

– Environmental protection field: Used to neutralize acidic wastewater and reduce the pH value of water bodies.